Alexey S. Peshkovsky, Continuous industrial-scale processing of liquids by high-amplitude ultrasound, Pacifichem 2015, Honolulu, Hawaii, USA, December 16, 2015.

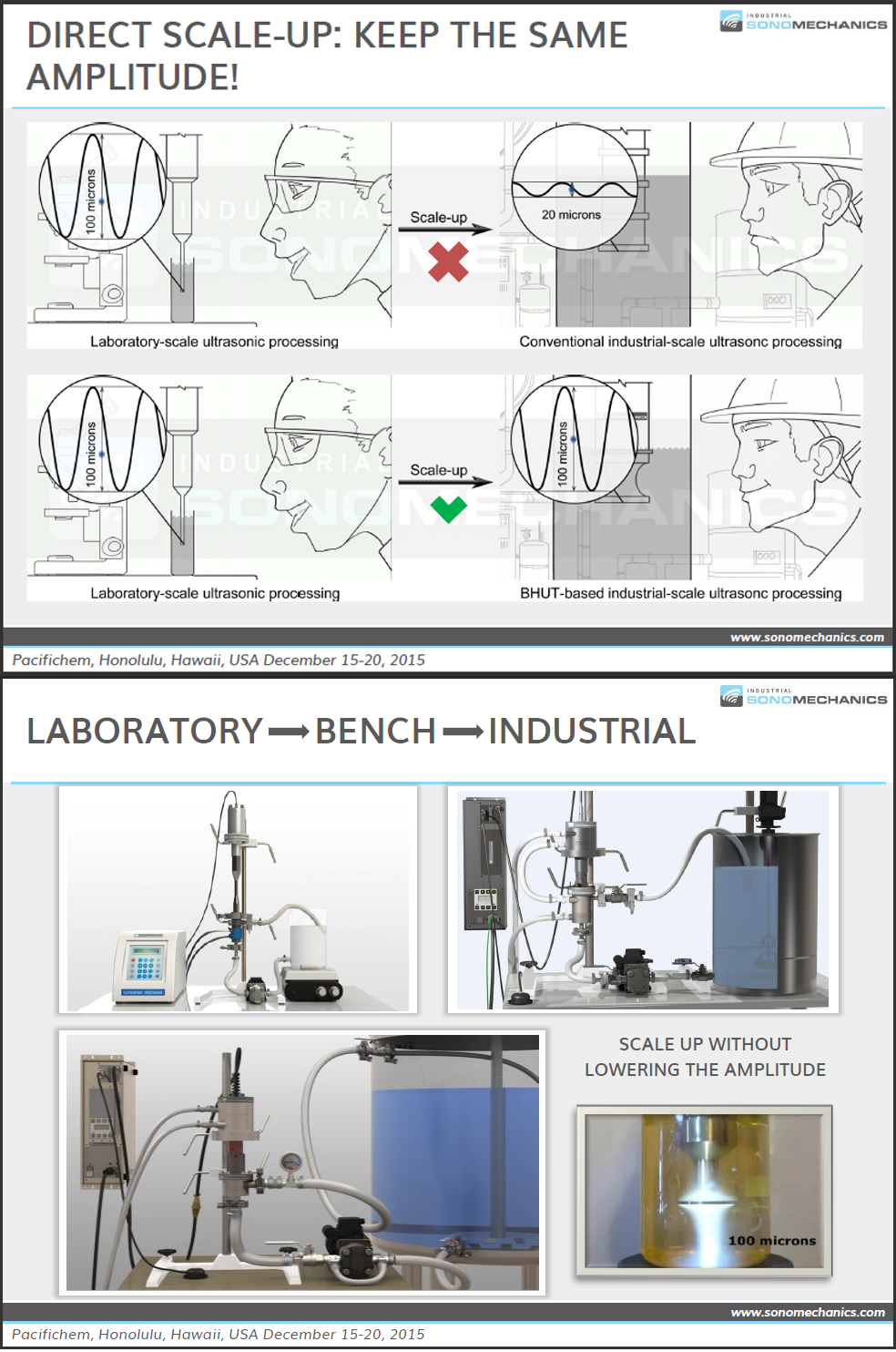

High-amplitude ultrasonic processing (HUP) is an attractive potential alternative to high-pressure homogenization (HPH) and bead milling (BM), which are currently established as commercial-scale technologies of choice for such processes as nano-emulsification, wet milling and cell disruption. In addition, HUP can be applied in many processes where HPH and BM are not commonly used, including liquid degassing, crude oil desulfurization, biodiesel production, water and beverage sterilization, etc. The challenge for HUP, however, has been bridging the gap between laboratory research and its industrial implementation. Due to limitations of conventional ultrasonic technology, scaling up has not been possible without significant reduction in ultrasonic amplitudes, diminishing the intensity of cavitation-generated shear forces and compromising the final product quality. This limitation has been overcome with Barbell Horn Ultrasonic Technology (BHUT), which permits constructing bench and industrial-scale processors operating at high ultrasonic amplitudes. In this presentation, main principles of BHUT are described and its operation is exemplified by four continuous-flow processes: nano-emulsification, wet milling, cell disruption and liquid degassing. Using BHUT, laboratory to industrial productivity scale-up factors of approximately 50 are shown to be possible to achieve without any reduction in the final product quality, allowing HUP to effectively compete with HPH and BM in many commercial application areas.

Industrial Sonomechanics is a R&D, equipment design and process consulting firm, specializing in high-power ultrasonic technology for liquid treatment. Our mission is to help businesses implement their ultrasound-assisted processes on lab, pilot and industrial scales.

[fa icon="phone"] 786-233-9255

[fa icon="envelope"] contact@sonomechanics.com

[fa icon="home"] 7440 SW 50th Terrace #110, Miami FL 33155