The ISP-3000 industrial-scale ultrasonic liquid processor is a Barbell Horn Ultrasonic Technology (BHUT)-based system designed for high-volume production. It can be implemented in two processing modes: flow-through and batch.

Although this ultrasonic processor is supplied mostly pre-assembled and ready-to-use, knowing how to put it together can be helpful. In this blog post we provide step-by-step assembly instructions for the ISP-3000 configured in the flow-through mode.

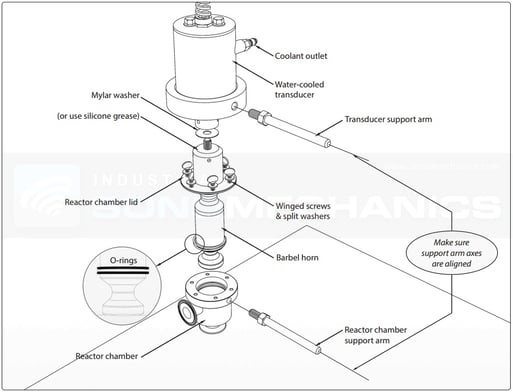

ASSEMBLY INSTRUCTIONS:To begin, please review the user's manual and familiarize yourself with the processor's components shown in the schematic below:

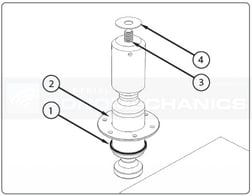

1. Place the top O-ring above the flange of the Barbell horn.

2. Place the reactor chamber lid above the top O-ring.

3. Make sure the connecting stud is tightly threaded into the horn.

4. Place the Mylar acoustic washer over the connecting stud. Make sure you use only one Mylar acoustic washer.

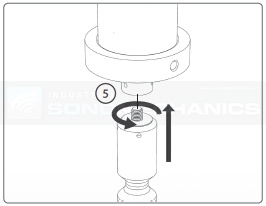

5. Thread the horn all the way into the transducer by hand.

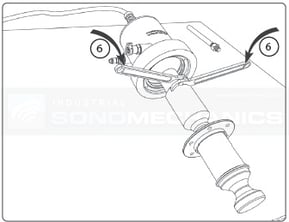

6. Tighten the assembly using the provided spanner wrenches:

a) Insert the pin of the first spanner wrench into a hole in the transducer’s front mass and set it up to provide counterclockwise torque.

b) Insert the pin of the second spanner wrench into a hole in the horn’s input end and set it up to provide clockwise torque.

c) Tighten by firmly pressing down with your palms on the wrenches, using the weight of your body. Please note, that power overload error during system operation may indicate an insufficiently tightened transducer-horn assembly.

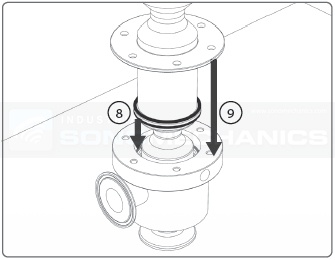

7. Place the bottom O-ring below the flange of the Barbell horn.

8. Insert the Barbell horn into the reactor chamber until the bottom O-ring is in contact with the chamber.

9. Lower the reactor chamber lid until it is in contact with the top O-ring.

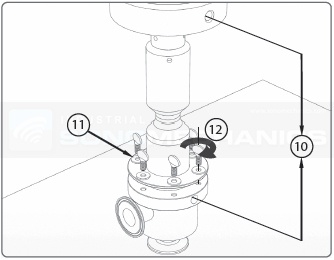

10. Align the transducer's and reactor chamber's support arm holes.

11. Insert the winged screws with split washers through the reactor chamber lid holes.

12. Thread the winged screws into the body of the reactor chamber by hand. Tighten evenly on all sides using a crossing pattern.

We are now going to place the assembled ultrasonic stack on the support stand.

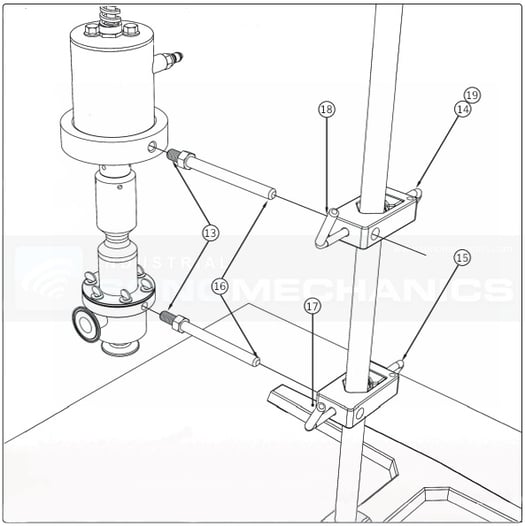

13. Thread the support arms into the transducer and the reactor chamber and tighten the counter-nuts.

14. Secure the top clamp holder on the support stand rod.

15. Adjust the position and secure the bottom clamp holder such that both support arms can be accomodated.

16. Slide both support arms into the corresponding clamp holders.

17. Secure the reacor chamber support arm in the bottom clamp holder.

18. Secure the transducer support arm in the top clamp holder.

19. Momentarily loosen and retighten the top clamp holder to remove any strain in the assembly.

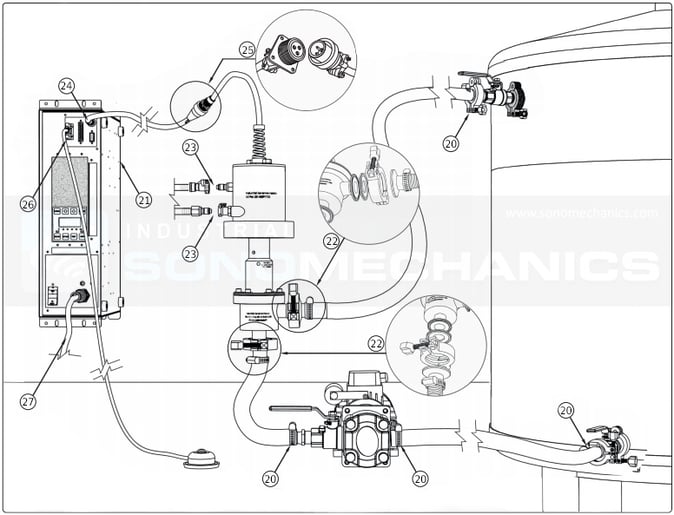

20. Assemble all hose/piping connections for peripherral equipment.

21. Hang the generator on a wall or place it into a rack.

22. Assemble the reactor chamber inlet and outlet hose/piping connections.

23. Attach transducer cooling lines to a chiller.

24. Connect the ultrasound cable to the generator.

25. Assemble the connection between the ultrasound cable and the transducer.

26. Connect the remote button ON/OFF switch to the generator.

27. Plug the generator power cable into a 208 - 240 VAC outlet.

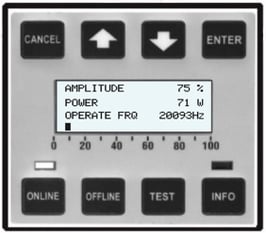

28. Before putting any liquid through the reactor chamber, briefly activate the ultrasonic output to check the power reading.

Make sure you use an adequate ear protection (such as ear muffs) while operating the system!

|

POWER TEST INSTRUCTIONS:

- Liquid present in the reactor chamber, - Barbell horn insufficiently tightened to the transducer, - Reactor chamber lid tightened unevenly, - Strain in the assembly.

|

The ISP-3000 processor is now assembled and ready for continuous operation!

These assembly instructions are also available in the printer-friendly PDF format. For further information, please download the ISP-3000 user's manual.

ISP-3000 Assembly Instructional Video: