In our previous blog post on ultrasonic cavitation in liquids, we described it as a cloud of low-pressure voids (a.k.a., vacuum bubbles or cavities) that grow, briefly oscillate and finally asymmetrically implode with great intensity. This effect causes extreme local temperatures and pressures, which can produce free radicals and give rise to many chemical (sonochemical) reactions. It also generates extremely powerful micro-jets and enormous shear forces, which promote a variety of physical (mechanical) processes. In some instances, these effects can be clearly seen as they occur. In this post, we provide such visual examples of chemical and mechanical processes.

Acoustic Cavitation: Visual Examples of Chemical & Physical Processes

[fa icon="calendar'] Apr 10, 2016 12:45:02 PM / by Alexey Peshkovsky, Ph.D. posted in Theory of Ultrasonic Processing

Acoustic Cavitation: The Driving Force Behind Ultrasonic Processing

[fa icon="calendar'] Jan 2, 2016 5:01:34 PM / by Alexey Peshkovsky, Ph.D. posted in Ultrasonic Degassing, Theory of Ultrasonic Processing, Extraction, Food & Beverage, Wet Milling and Dispersing

Liquids exposed to high-intensity ultrasound can undergo acoustic cavitation. This phenomenon can typically be seen as a cloud of bubbles forming in the vicinity of the ultrasonic source (e.g., ultrasonic horn) and heard as an intense hissing noise. Cavitation is the formation of low-pressure voids (a.k.a., vacuum bubbles or cavities) in the liquid, which grow, briefly oscillate and then asymmetrically implode with great intensity.

6 Frequently Used Terms in Ultrasonic Processing of Liquids

[fa icon="calendar'] Dec 1, 2015 4:39:00 PM / by Alexey Peshkovsky, Ph.D. posted in Ultrasonic Processing Systems, Theory of Ultrasonic Processing, Extraction

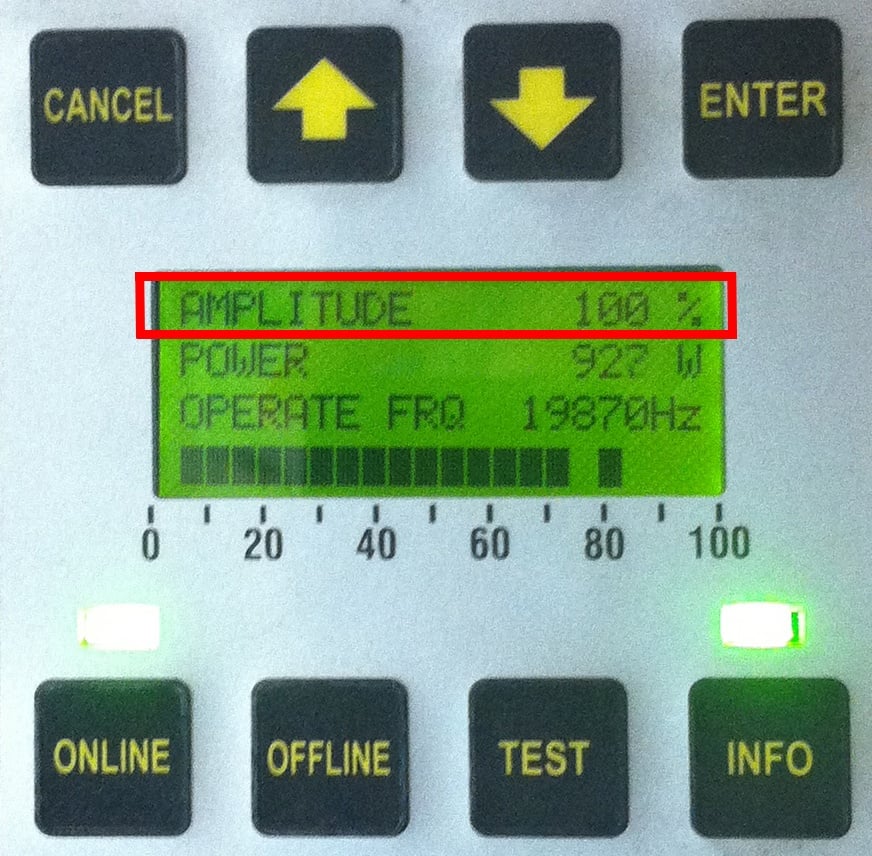

This blog post focuses on six common terms used in conjunction with ultrasonic processing: ultrasonic amplitude, power, frequency, power intensity, power density and processing rate.

Whether you use ultrasonic processing for making nanoemulsions, milling pharmaceutical crystals, degassing, extracting botanical oils, manufacturing bio-fuels, dispersing pigments, disrupting cells or enhancing a chemical process, there are several general terms you need to be familiar with. Knowing these terms and keeping track of the corresponding parameters will insure reproducibility of results and simplify process-related discussions with your peers.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)