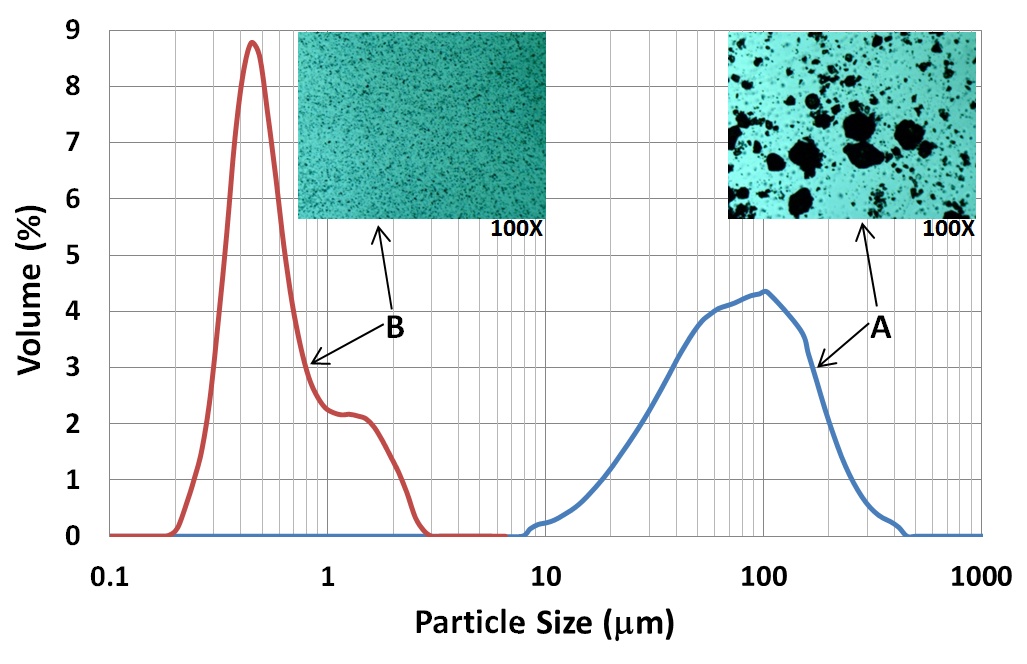

Salsalate is part of a class of naturally occurring chemicals known as salicylates, which are among the oldest prescribed medicinal anti-inflammatories [1]. The most common salicylate is acetylsalicylic acid (ASA) (coined Aspirin by Bayer in 1899) and its main biochemical function is the reduction of inflammation and fever via the inhibition of cyclooxygenase enzymes (COX) [2]. Over the last century, it has been suggested that salicylates could have other medicinal benefits, specifically in the treatment of mild cases of diabetes [3, 4, 7]. Aspirin has been administered to patients with pre-diabetes/obesity in order to hinder the evolution of the disease. Unfortunately, inhibition of COX by Aspirin results in abnormalities in bleeding, platelet aggregation and gastric regulation [8, 9]. In retribution, medical practitioners have looked to salsalate [14] to provide treatment to diabetes patients as it has similar anti-inflammatory properties to Aspirin yet has been shown to be significantly less gut damaging [10]. To maximize the bioavailability of the drug and promote effective therapy, nano-crystallization of salsalate clusters must be performed to reduce their median particle size below one micron [12].

High-intensity ultrasonic liquid processing provides a simple means for such particle comminution. In this post we demonstrate how salsalate crystals can be brought to sub-micron median particle sizes by ultrasonic milling with Industrial Sonomechanics bench-scale processor, BSP-1200, configured in the flow-through mode.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)