The demand for water-soluble mushroom extracts is surging, driven by the growing interest in their therapeutic, health-promoting benefits. Water-soluble extracts are highly desirable due to their enhanced, rapid absorption and ease of incorporation into various consumer products such as beverages, foods, and nutritional supplements [1].

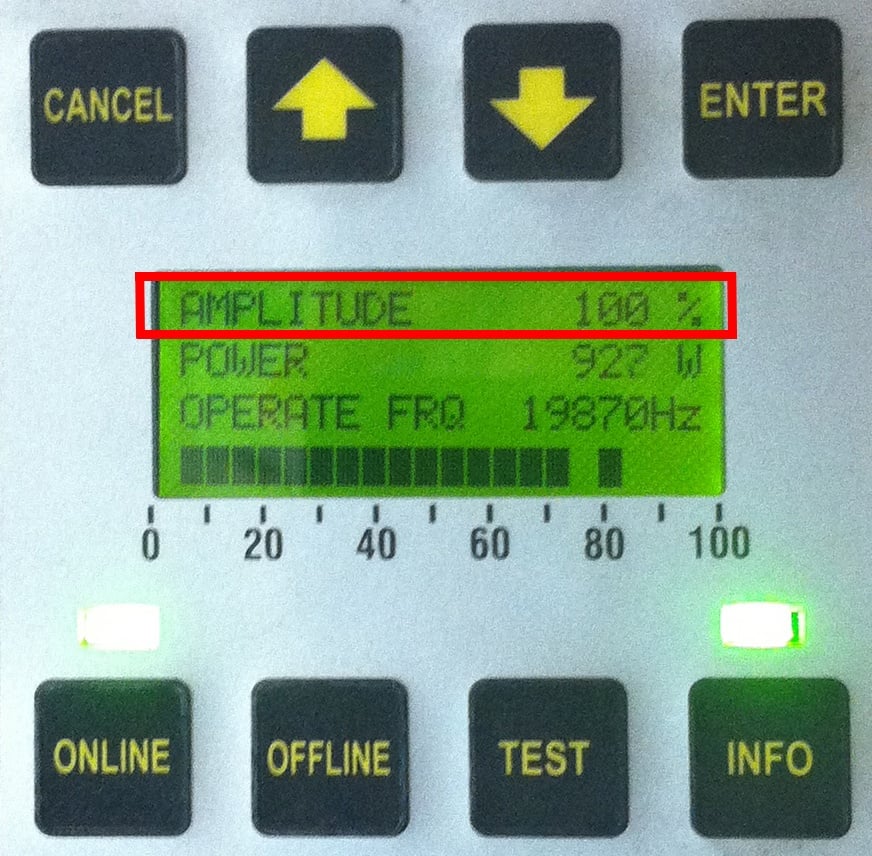

Producing water-soluble mushroom extracts in liquid or powdered forms involves two important processing steps: (1) extraction of the bioactive compounds from mushrooms and (2) their subsequent nano-emulsification to achieve aqueous solubility. Industrial Sonomechanics (ISM) has perfected these processes to ensure that our customers can manufacture the highest-quality finished products infused with water-soluble mushroom extracts.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)