Sterile filtration is an important post-processing step of ultrasonic nano-emulsification - a process that converts cannabis extracts and/or other hydrophobic bioactives into a water-compatible form. In this article, I will summarize the steps of the nano-emulsification process carried out with BHUT-based ultrasonic equipment and NanoStabilizer®-LT, list the main advantages of the resulting water-compatible nanoemulsions, and explain why sterile filtration is always necessary at the end. Answers to several FAQs will also be provided.

Ultrasonic nano-emulsification steps

Since NanoStabilizer®-LT already includes all the necessary ingredients (food-grade carrier oils, emulsifiers, and preservatives), no formulation development is necessary. The nano-emulsification process simply consists of:

- Pre-mixing your cannabis extract or isolate with NanoStabilizer®-LT in the ratio of 1:5;

- Stirring the resulting premix into distilled water and recirculating through a Barbell Horn Ultrasonic Technology (BHUT)-based processor until the nanoemulsion becomes translucent;

- Sterile-filtering and collecting the translucent nanoemulsion in a light-protected, autoclaved container.

|

1. Pre-mixing cannabis extract with NanoStabilizer®-LT |

2. Stirring the premix into water and ultrasonically processing | 3. Sterile-filtering and collecting the resulting nanoemulsion |

|

|

|

Why nano-emulsify cannabis extracts?

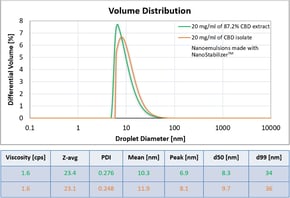

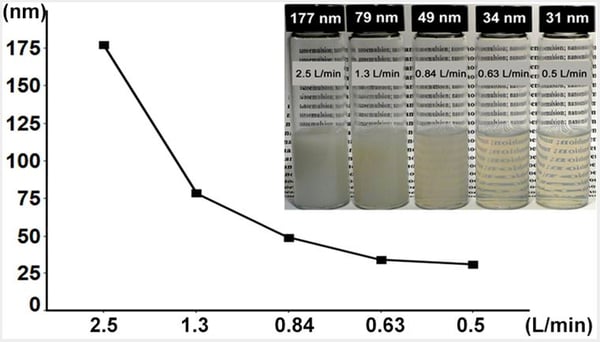

As shown in the figures below, translucent nanoemulsions produced from cannabis and/or other bioactive extracts by BHUT-based ultrasonic processing in combination with NanoStabilizer®-LT have extremely small median droplet sizes, in the range of 10 - 30 nm.

|

|

Having droplets that small affords a number of important advantages, including:

- Complete water-compatibility;

- Permanent stability;

- Optical clarity of the finished product;

- Increased bioavailability and accelerated onset of action;

- Ability to easily pass through sterile filters.

Why sterile-filter cannabis extract nanoemulsions?

Passing a translucent nanoemulsion through a hydrophilic filter membrane with 220 nm pores removes practically all particulate contamination it may contain, including any microorganisms (sterilization), dust, titanium particles shed by the ultrasonic horn, leftover plant matter, etc. It is, therefore, unnecessary to manufacture such nanoemulsions under aseptic conditions, which significantly reduces processing costs. Since translucent nanoemulsions have much smaller droplet sizes (< 100 nm) than sterile-filter membrane pores (220 nm), they are able to flow though such filters without having any of the THC and/or CBD-containing oil droplets rejected by the membrane. The hydrophilic character of the filter membrane ensures that the hydrophobic oil droplets have low affinity for the membrane material and will not stick to it as long as they can fit through the pores and are carried by the liquid flow. You should, however, always make sure that your nanoemulsion is translucent before attempting to sterile filter it. Otherwise, some of the oil droplets may not fit through the pores and rapidly clog the filter.

What filter types are available?

Disposable syringe filters

Disposable syringe filters

Sterilizing syringe filters are available in the form of disposable cartridges that attach to the end of a syringe. These simple devices comprise a plastic housing and a disk-shaped membrane with 220 nm pore sizes. For filtering oil-in-water nanoemulsions, the appropriate membrane materials include nylon, polyethersulfone, cellulose acetate, regenerated cellulose, anopore, glass fiber, hydrophilic polypropylene, hydrophilic polyvinylidene fluoride, and hydrophilic polytetrafluoroethylene. Syringe filters are only suitable for working with small liquid volumes. Typically, it is possible to pass about 20 - 30 ml of translucent nanoemulsion through a 25 mm-diameter sterilizing syringe filter before it starts to resist the liquid flow and needs to be replaced.

Disposable vacuum filtration systems

Disposable vacuum filtration systems

These convenient disposable filtration systems typically comprise a polystyrene filter funnel and storage bottle (with a separate cap), joined by an adapter ring, which includes a fitting for connecting the assembly to a vacuum pump. The funnel comes with a 220 nm-pore hydrophilic membrane, made from similar materials to those used in syringe filters. All components are commonly supplied sterile and individually packaged. Vacuum filtration systems allow working with larger amounts of translucent nanoemulsions than syringe filters - up to about 500 ml can typically be filtered with each disposable unit.

Reusable in-line filters

Reusable in-line filters

In-line sterilizing filters are typically constructed of a hydrophilic hollow fiber material (thousands of long, hollow filaments with 220 nm pores) packed into a plastic cartridge. They may also contain activated carbon, and it is important to make sure that the type you choose for filtering your nanoemulsions comes without it, otherwise the potency of your product may be diminished. These devices are reusable and can typically filter many liters of translucent nanoemulsion before they need to be back-flushed with purified water to clear out the particulates retained by the membrane. Typically, a peristaltic pump is used to push the nanoemulsion product through such a filter at a relatively low flow rate (about 0.5 L/min). ISM offers in-line sterilizing filters in conjunction with NanoStabilizer®-LT.

More FAQs:

1. Do my nanoemulsion particle sizes change after filtration?

No. Sterile filtration of translucent nanoemulsions does not change their particle sizes.

2. What about my cannabis oil? Could it inadvertently get filtered out?

Not from correctly prepared translucent nanoemulsions. Sterilizing filters (without activated carbon) do not remove any active ingredients, excipients, carrier oils, preservatives or any other formulation components of such nanoemulsions.

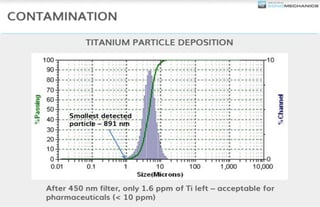

3. What about the horn wear and titanium particles shed by it? Will they all get filtered out?

Yes. The Barbell horn is a consumable part of an ultrasonic system and does wear out. This is normal, and the titanium particles shed by the horn are easily removed by filtration. The graph on the right shows the size distribution of such titanium particles (measured by Laser Diffraction with Mictrotrac Analyzer S3500). Practically all particles are larger than 1 micron, which means that passing your finished nanoemulsion through a filter with 450 nm or 220 nm pores will remove them completely (as determined by Inductively Coupled Plasma Mass Spectrometry with Agilent 7500 ICP-MS). Filters with 220 nm pores are recommended whenever possible because they also get rid of all microbial contamination.

Yes. The Barbell horn is a consumable part of an ultrasonic system and does wear out. This is normal, and the titanium particles shed by the horn are easily removed by filtration. The graph on the right shows the size distribution of such titanium particles (measured by Laser Diffraction with Mictrotrac Analyzer S3500). Practically all particles are larger than 1 micron, which means that passing your finished nanoemulsion through a filter with 450 nm or 220 nm pores will remove them completely (as determined by Inductively Coupled Plasma Mass Spectrometry with Agilent 7500 ICP-MS). Filters with 220 nm pores are recommended whenever possible because they also get rid of all microbial contamination.

4. Do I need to filter my cannabis nanoemulsion even if there is no visible titanium contamination?

Yes. Filtering your final nanoemulsion is important, not only for removing titanium particles, but also for sterilization, which is required for food and beverage products.

To receive an email update when a new blog post is published, please subscribe below:

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)