The effect of operating an ultrasonic liquid processor (sonicator) on hearing is a question that arises often during discussions with our customers. The noise made by sonicators can be described as intense "hissing", which, if precautions are not taken, can be loud enough to cause significant discomfort or even lead to hearing loss. We performed a series of noise level measurements to determine how loud different types of ultrasonic processors really are.

The effect of operating an ultrasonic liquid processor (sonicator) on hearing is a question that arises often during discussions with our customers. The noise made by sonicators can be described as intense "hissing", which, if precautions are not taken, can be loud enough to cause significant discomfort or even lead to hearing loss. We performed a series of noise level measurements to determine how loud different types of ultrasonic processors really are.

Understanding Noise

Noise is unwanted sound, which is commonly a superposition of pressure waves of different frequencies (pitches) that travel through a medium (most commonly air) and can be detected by a person's ear. The loudness or intensity of noise is expressed in dBA (weighted decibels), which is a unit that takes into account sound intensities at all audible frequencies, weighted to correspond to the frequency response of human hearing. The decibel is a logarithmic unit, a number that represents how much a sound differs from a reference point. The louder the sound, the greater is its decibel value. A 3 dBA increase in noise is just barely perceptible to the human ear, while a 10 dBA increase generally feels as a doubling of loudness [1].

How Loud is Too Loud?

Occupational hearing loss is the most common work-related injury in the United States. According to the Center for Disease Control and Prevention (CDC), approximately 22 million U.S. workers are exposed to hazardous noise levels at work [2]. Both the level of noise and the length of exposure can put you at risk. Below are several guidelines provided by the National Institute of Deafness and Other Communication Disorders (NIDCD) [3]:- The human ear can tolerate sound up to about 120 dBA;

- Prolonged exposure (over 8 hours) to any noise at or above 85 dBA is associated with gradual hearing loss;

- It is recommended that regular unprotected exposure to 100 dBA of noise be minimized to 15 minutes or less;

- Regular unprotected exposure to noise at 110 dBA for more than 1 minute can cause permanent hearing loss.

Common Sources of Noise

Some common sources of noise are presented in the table below [2]:

|

Source of noise |

dBA |

|---|---|

|

Normal conversation |

60 |

|

Heavy city traffic |

85 |

|

Ambulance siren |

120 |

|

Chain saw, Rock concert |

110 |

|

Motorcycle |

95 |

Ultrasonic Noise Measurements Performed at Our Facility: Materials and Methods

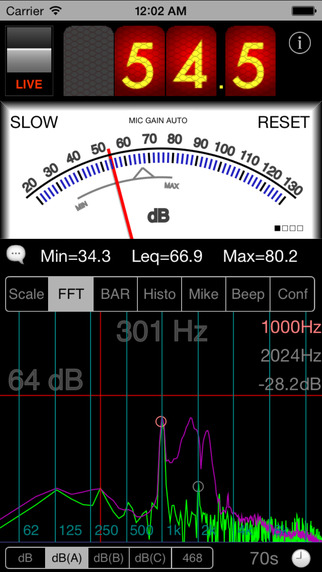

Various instruments and techniques may be used to measure sound levels. The choice depends on the workplace type and information needed. The most common instruments used for measuring noise are the sound level meter, the integrating sound level meter and the noise dosimeter. There are also several applications that make it possible to use common devices, such as smart phones, for conducting accurate noise measurements. In this study, we used the iPhone with the SPLnFFT software, which was shown by the National Institute for Occupational Safety and Health to provide excellent agreement with actual reference values and be reliable for occupational noise exposure assessments [4].

The experiments were conducted at Industrial Sonomechanics' product testing facility. We tested four ultrasonic processors operating in both batch and flow-through modes at the frequency of approximately 20 kHz. Noise level data were collected at the distances of two and twenty feet from the processors. Ultrasonic amplitude settings of 90 and 40 microns were tested with water, soybean oil and propylene glycol using each processor.

Results and Discussion

Neither the amplitude setting nor the type of tested liquid had significant effects (< 3 dBA) on the observed noise levels. The results presented in the table below are for water at the amplitude setting of 90 microns.

| Source of Noise | dBA at 2' away | dBA at 15' away |

|---|---|---|

| Background (pump, chiller, etc.) | 69 | 69 |

| Major brand 500 W ultrasonic processor, batch mode | 107 | 95 |

| LSP-600 processor, batch mode | 109 | 99 |

| LSP-600 processor, flow-through mode | 106 | 94 |

|

BSP-1200 processor, batch mode |

103 | 90 |

| BSP-1200 processor, flow-through mode | 106 | 92 |

| ISP-3600 processor, flow-through mode | 109 | 101 |

This data clearly shows that operating an ultrasonic processor without adequate hearing protection for both the operator and other workers in the vicinity of the equipment is unsafe. Since additional sources of noise may worsen the problem, professional assessment should always be performed in each specific work environment to determine what noise reduction is required for compliance with local regulations.

Recommended Noise-Reduction Methods

In order to bring the ultrasonic processor noise to an acceptable level, a minimum reduction of ~ 20 dBA (for the United States) and ~25 dBA (for Europe) is required. The simplest solution is to use over-the-head ear muffs with at least 25 dBA of attenuation.  Ear muffs are inexpensive and widely available, however, their use may not be convenient at locations shared by many co-workers.

Ear muffs are inexpensive and widely available, however, their use may not be convenient at locations shared by many co-workers.

An alternative solution is to place your ultrasonic processor in a noise reduction enclosure (also known as sound abating enclosure, sound proof enclosure). For laboratory sonicators, such enclosures are available, although it is always important to make sure they provide appropriate attenuation values.

Industrial Sonomechanics has recently developed compact noise reduction enclosure, NRE-30, for the LSP-600, BSP-1200 and ISP-3600 ultrasonic processors. The NRE-30 is also customizable to fit other types of equipment (third-party sonicators, homogenizers, mixers, pumps, etc.). These enclosure is described in details in this blog post. Please contact us if you would like a quotation for the NRE-30 sound enclosure or you can also purchase it directly on our online store by using the below button.

We look forward to your comments and questions.

Schedule a call with a product specialist!

References:

1. Chapter 10: Noise, Sugar Hill Rezoning, EIS Documents, 2006.

Retrieved from http://www.nyc.gov/html/dcp/pdf/env_review/sugar_hill/10_feis.pdf

2. Noise and Hearing Loss Prevention, Center for Disease Control and Prevention, 2013.

Retrieved from http://www.cdc.gov/niosh/topics/noise

3. How Loud is Too Loud? Bookmark, National Institute of Deafness and Other Communication Disorders, July 2011.

Retrieved from http://www.nidcd.nih.gov/health/hearing/pages/ruler.aspx

4. Kardous, C. A., & Shaw, P. B., Evaluation of smartphone sound measurement applications, The Journal of the Acoustical Society of America, 135(4), EL186-EL192, 2014.

Retrieved from http://scitation.aip.org/content/asa/journal/jasa/135/4/10.1121/1.4865269

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)