Salsalate is part of a class of naturally occurring chemicals known as salicylates, which are among the oldest prescribed medicinal anti-inflammatories [1]. The most common salicylate is acetylsalicylic acid (ASA) (coined Aspirin by Bayer in 1899) and its main biochemical function is the reduction of inflammation and fever via the inhibition of cyclooxygenase enzymes (COX) [2]. Over the last century, it has been suggested that salicylates could have other medicinal benefits, specifically in the treatment of mild cases of diabetes [3, 4, 7]. Aspirin has been administered to patients with pre-diabetes/obesity in order to hinder the evolution of the disease. Unfortunately, inhibition of COX by Aspirin results in abnormalities in bleeding, platelet aggregation and gastric regulation [8, 9]. In retribution, medical practitioners have looked to salsalate [14] to provide treatment to diabetes patients as it has similar anti-inflammatory properties to Aspirin yet has been shown to be significantly less gut damaging [10]. To maximize the bioavailability of the drug and promote effective therapy, nano-crystallization of salsalate clusters must be performed to reduce their median particle size below one micron [12].

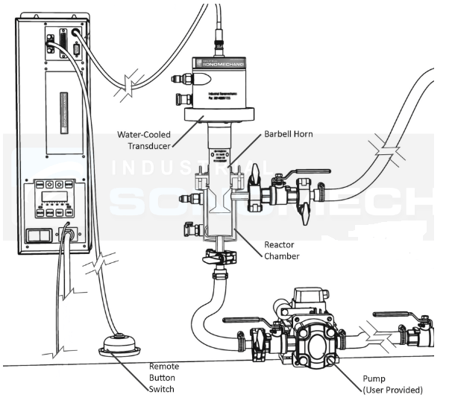

High-intensity ultrasonic liquid processing provides a simple means for such particle comminution. In this post we demonstrate how salsalate crystals can be brought to sub-micron median particle sizes by ultrasonic milling with Industrial Sonomechanics bench-scale processor, BSP-1200, configured in the flow-through mode.

Materials and Methods

The ultrasonic nano-crystallization process was conducted using:

- Ultrasonic processor: BSP-1200 configured in the flow-through mode

- Incorporated horn: Half-wave Barbell horn, amplitude = 80 µm, frequency = 20 kHz

- Active ingredient: salsalate, initial median particle size, d50 ≈ 72 µm

- Medium: distilled water

- Surfactant: Tween 80

- Co-surfactant: isopropyl alcohol

- Peripherals: magnetic stir-plate, pump, storage tank, microscope, particle size analyzer

Two samples were prepared as shown below:

|

|

Sample 1 |

Sample 2 |

||

|

Mass [g] |

Mass Percentage [%] |

Mass [g] |

Mass Percentage [%] |

|

|

Water |

965 |

96.5 |

985 |

98.5 |

|

Tween 80 |

5 |

0.5 |

5 |

0.5 |

|

Isopropyl Alcohol |

20 |

2.0 |

0 |

0 |

|

Salsalate |

10 |

1.0 |

10 |

1.0 |

Table 1. Salsalate sample components.

Small-chain alcohols (e.g., isopropyl alcohol) are commonly used in pharmaceutical nano-crystallization processes to increase the compatibility of water and the hydrophobic active to be nano-crystalized [5, 6]. To test the preceding claim and determine how the presence of a small-chain alcohol affects the final salsalate particle size, Sample 1 contained 2 % of isopropyl alcohol while Sample 2 was prepared without it.

The samples were premixed on a magnetic stir plate and recirculated through the reactor chamber without sonication for 10 minutes. Ultrasonic output was then initiated, and each sample was processed continuously for 4.5 hours. Both the transducer and reactor chamber were cooled with chilled water (~10 °C), maintaining the processed liquid temperature at 25 °C.

Figure 1. Schematic of BSP-1200 in the flow-through mode.

Results and Discussion

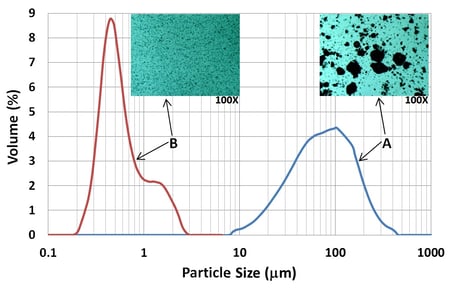

Figure 2. Particle size distribution before (blue) and after (red) sonication of Sample 1.

Figure 2. Particle size distribution before (blue) and after (red) sonication of Sample 1.

The blue line (A) shows the particle size distribution for the unprocessed sample, which had the median particle diameter d50 = 72.02 µm. As pictured in the superimposed microscopic image, the unprocessed sample showed large particles of varying sizes. The red line (B) corresponds to the particle size distribution of Sample 1, for which the median particle diameter was ultrasonically reduced to d50 = 0.499 µm. For comparison, the median particle diameter of the processed Sample 2 was higher: d50 = 0.615 µm, which can be attributed to the absence of isopropyl alcohol in this formulation.

Aside from the overall reduction in d50, it is evident that ultrasonic exposure promotes a near uniform distribution of particle sizes. This observation is qualified by the steepness of line B and that nearly all processed salsalate particles achieved a particle diameter in the sub-micron regime (d84 = 1 µm).

References

- Nunn, John F. Ancient Egyptian Medicine. British Museum Press, 1996.

- Flower, R. “What Are All the Things That Aspirin Does?” British Medical Journal, vol. 327, no. 7415, 2003, pp. 572–573.

- Reid, James, et al. “Aspirin and Diabetes Mellitus.” British Medical Journal, 9 Nov. 1957, pp. 1071–1074.

- Williamson, R. T. “On the Treatment of Glycosuria and Diabetes Mellitus with Sodium Salicylate.” British Medical Journal, vol. 1, no. 2100, 30 Mar. 1901, pp. 760–762.

- Burlage, Henry M., and Doris Bullard Hawkins. “Pharmaceutical Applications of Isopropyl Alcohol. I. As a Solvent in Pharmaceutical Manufacturing .” Journal of the American Pharmaceutical Association (Scientific Ed.), vol. 35, no. 12, 1946, pp. 379–384.

- Choi, Suk-Young, et al. “Effect of Short-Chain Alcohols as Co-Surfactants on Pseudo-Ternary Phase Diagrams Containing Lecithin.” Korean Journal of Chemical Engineering, vol. 16, no. 3, 1999, pp. 377–381.

- Colewell, John A. “Aspirin Therapy in Diabetes.” Diabetes Care, vol. 27, no. Supplement 1, Jan. 2004, pp. S72–S73.

- Aspirin Side Effects. Drugs.com. Retrieved from www.drugs.com/sfx/aspirin-side-effects.html.

- Gartner, Arnold H. “Aspirin-Induced Gastritis and Gastrointestinal Bleeding.” The Journal of the American Dental Association, vol. 93, no. 1, July 1976, pp. 111–117.

- Cryer, Byron, et al. “Comparison of Salsalate and Aspirin on Mucosal Injury and Gastroduodenal Mucosal Prostaglandins.” Gastroenterology, vol. 99, no. 6, 1990, pp. 1616–1621.

- Gao, Yuan, et al. “Crystallization Methods for Preparation of Nanocrystals for Drug Delivery System.” Current Pharmaceutical Design, vol. 21, no. 22, 2015, pp. 3131–3139.

- Vaughn, Charles. Use of Salsalate with or without Caffeine and with or without Omega 3, and Other Pharmaceutical Compounds in a Distinctively Unique Nano-particulate Capsule and Tablet. Charles Vaughn, assignee. Patent US 20110064813 A1. 17 Mar. 2011

- Liversidge, Gary G., and Kenneth C. Cundy. “Particle Size Reduction for Improvement of Oral Bioavailability of Hydrophobic Drugs: I. Absolute Oral Bioavailability of Nanocrystalline Danazol in Beagle Dogs.” International Journal of Pharmaceutics, vol. 125, no. 1, 17 Oct. 1995, pp. 91–97.

- Goldfine, Allison B., et al. “Use of Salsalate to Target Inflammation in the Treatment of Insulin Resistance and Type 2 Diabetes.” Clinical and Translational Science, vol. 1, no. 1, May 2008, pp. 36–43.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)