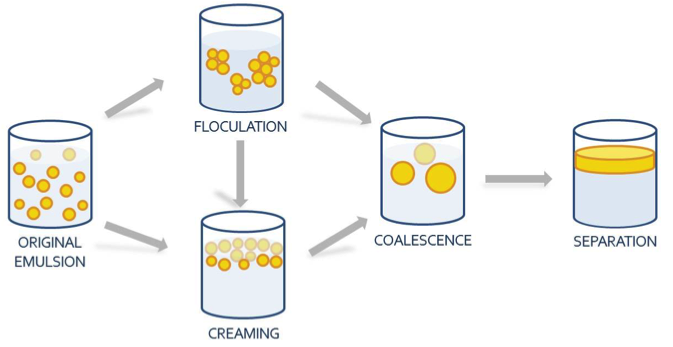

One of the primary concerns when formulating oil-in-water (O/W) nanoemulsions is the stability of the finished product. Destabilization of an O/W nanoemulsion can occur due to several physical, chemical or biological processes that deteriorate its quality over time. Understanding and avoiding these processes is paramount to ensuring that products based on cannabis extract nanoemulsions (a.k.a. "water-soluble" CBD and THC) have a long and predictable shelf-life. In this post, common nanoemulsion destabilization pathways will be described, along with the most effective strategies to avoid them.

Shlomo Leibtag

Recent Posts

How to Formulate Cannabis Extract Nanoemulsions with a Long Shelf Life

[fa icon="calendar'] Oct 8, 2019 9:30:00 AM / by Shlomo Leibtag posted in Emulsion-based Products, Medical Cannabis

Ultrasonic Nano-Crystallization of Salsalate for Improved Bioavailability

[fa icon="calendar'] Dec 14, 2017 10:00:00 AM / by Shlomo Leibtag posted in Wet Milling and Dispersing

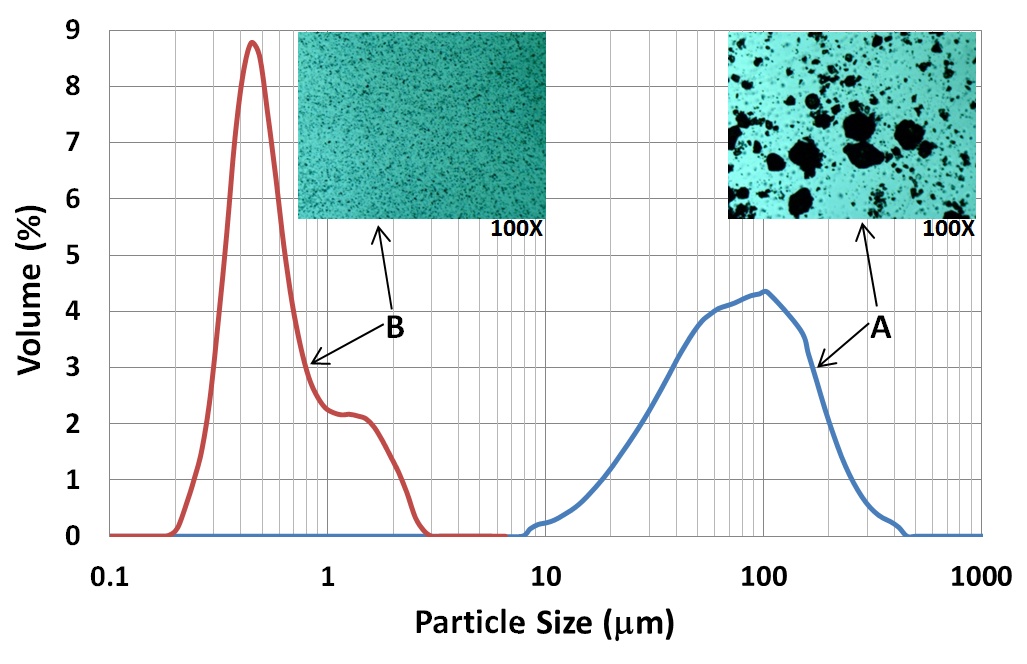

Salsalate is part of a class of naturally occurring chemicals known as salicylates, which are among the oldest prescribed medicinal anti-inflammatories [1]. The most common salicylate is acetylsalicylic acid (ASA) (coined Aspirin by Bayer in 1899) and its main biochemical function is the reduction of inflammation and fever via the inhibition of cyclooxygenase enzymes (COX) [2]. Over the last century, it has been suggested that salicylates could have other medicinal benefits, specifically in the treatment of mild cases of diabetes [3, 4, 7]. Aspirin has been administered to patients with pre-diabetes/obesity in order to hinder the evolution of the disease. Unfortunately, inhibition of COX by Aspirin results in abnormalities in bleeding, platelet aggregation and gastric regulation [8, 9]. In retribution, medical practitioners have looked to salsalate [14] to provide treatment to diabetes patients as it has similar anti-inflammatory properties to Aspirin yet has been shown to be significantly less gut damaging [10]. To maximize the bioavailability of the drug and promote effective therapy, nano-crystallization of salsalate clusters must be performed to reduce their median particle size below one micron [12].

High-intensity ultrasonic liquid processing provides a simple means for such particle comminution. In this post we demonstrate how salsalate crystals can be brought to sub-micron median particle sizes by ultrasonic milling with Industrial Sonomechanics bench-scale processor, BSP-1200, configured in the flow-through mode.

Ultrasonic Dispersing and Wet-milling of Calcium Carbonate (CaCO3)

[fa icon="calendar'] Oct 6, 2016 6:29:11 PM / by Shlomo Leibtag posted in Wet Milling and Dispersing

Cement, and its paved derivative, concrete, is a widely-consumed material in any modern society: residential walkways, recreational parks and building construction are just some of the many uses of cement. This year, upwards of 80 million metric tons of cement will be processed in the United States alone [1].

As a building and support material, the two most important qualities of cement are its compressive strength (the capability to withstand an inward load) and its workability (the propensity of the cement paste to be deformable and fluidized). Unfortunately, these two qualities are not independent of each other.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)