In our previous blog post on ultrasonic cavitation in liquids, we described it as a cloud of low-pressure voids (a.k.a., vacuum bubbles or cavities) that grow, briefly oscillate and finally asymmetrically implode with great intensity. This effect causes extreme local temperatures and pressures, which can produce free radicals and give rise to many chemical (sonochemical) reactions. It also generates extremely powerful micro-jets and enormous shear forces, which promote a variety of physical (mechanical) processes. In some instances, these effects can be clearly seen as they occur. In this post, we provide such visual examples of chemical and mechanical processes.

In our previous blog post on ultrasonic cavitation in liquids, we described it as a cloud of low-pressure voids (a.k.a., vacuum bubbles or cavities) that grow, briefly oscillate and finally asymmetrically implode with great intensity. This effect causes extreme local temperatures and pressures, which can produce free radicals and give rise to many chemical (sonochemical) reactions. It also generates extremely powerful micro-jets and enormous shear forces, which promote a variety of physical (mechanical) processes. In some instances, these effects can be clearly seen as they occur. In this post, we provide such visual examples of chemical and mechanical processes.

Ultrasonically Induced Chemiluminescense: The Chemical Process Example

Alkaline solutions of luminol emit light when subjected to ultrasonic cavitation of sufficient intensity. Light emission occurs as a result of oxidative chemiluminescence involving sonochemically

generated HO· radicals, which can be used to photographically map the intensity of cavitation zones. The picture on the left shows this effect created in a 300 ml beaker using the LSP-500 ultrasonic processor. Cavitation was generated by an FBH-type Barbell horn operating at the amplitude of 100 microns. The image was taken in a dark room with the camera's ISO sensitivity of 1600 and exposure time of 1 minute.

Ultrasonic Production of a Translucent Nanoemulsion: The Physical Process Example

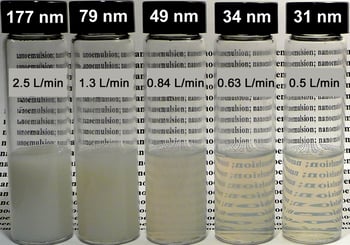

Translucent nanoemulsions are a special class of nanoemulsions that have extremely small droplet sizes (below 100 nanometers) and narrow droplet size distributions. These materials can be manufactured using high-intensity ultrasonic cavitation, which provides the necessary shear forces and micro-jets to break up oil droplets down to nanometer sizes. The picture on the left illustrates the dependence of the mean droplet size (MDS) on the production rate of a translucent soybean oil-in-water nanoemulsion, carried out with the ISP-3000 ultrasonic processor. Cavitation was generated by an HBH-type Barbell horn operating at the amplitude of 100 microns. It can be clearly seen how the emulsion becomes progressively more translucent as the MDS decreases. For further details on this process, please see this demonstration video.

Translucent nanoemulsions are a special class of nanoemulsions that have extremely small droplet sizes (below 100 nanometers) and narrow droplet size distributions. These materials can be manufactured using high-intensity ultrasonic cavitation, which provides the necessary shear forces and micro-jets to break up oil droplets down to nanometer sizes. The picture on the left illustrates the dependence of the mean droplet size (MDS) on the production rate of a translucent soybean oil-in-water nanoemulsion, carried out with the ISP-3000 ultrasonic processor. Cavitation was generated by an HBH-type Barbell horn operating at the amplitude of 100 microns. It can be clearly seen how the emulsion becomes progressively more translucent as the MDS decreases. For further details on this process, please see this demonstration video.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)