For the past two years, many businesses have been using our all-in-one NanoStabilizer®-LT to convert their cannabis extracts and other hydrophobic bio-actives into water-compatible, stable, translucent nanoemulsions. Most commonly, the conversion is done in order to enhance the bioavailability and accelerate the onset of action of cannabinoids and to infuse beverages without making them cloudy. Designed to work with Industrial Sonomechanics ultrasonic liquid processors, NanoStabilizer®-LT requires no formulation development experience and is compatible with a wide range of bio-actives, including most types of cannabis extracts and isolates, pharmaceutical ingredients, vitamins, essential oils, terpenes, etc. In this post, I provide answers to some of the most commonly asked questions about this popular product.

For the past two years, many businesses have been using our all-in-one NanoStabilizer®-LT to convert their cannabis extracts and other hydrophobic bio-actives into water-compatible, stable, translucent nanoemulsions. Most commonly, the conversion is done in order to enhance the bioavailability and accelerate the onset of action of cannabinoids and to infuse beverages without making them cloudy. Designed to work with Industrial Sonomechanics ultrasonic liquid processors, NanoStabilizer®-LT requires no formulation development experience and is compatible with a wide range of bio-actives, including most types of cannabis extracts and isolates, pharmaceutical ingredients, vitamins, essential oils, terpenes, etc. In this post, I provide answers to some of the most commonly asked questions about this popular product.

Q1. Could you provide a quick overview of how NanoStabilizer®-LT plays into the production of cannabis nanoemulsions? What else is required?

All-in-one NanoStabilizer®-LT was designed to simplify the ultrasonic production of high-quality translucent nanoemulsions of bio-active ingredients (e.g., cannabis extracts and isolates). It is a "plug-and-play" product (no R&D is needed from your end) that enables you to make nanoemulsions without having any formulation development or technical experience. The production process requires a starting bio-active ingredient (e.g., CBD or THC extract), one of our ultrasonic liquid processors, NanoStabilizer®-LT, distilled water, and some basic lab equipment. Detailed step-by-step instructions are provided with purchase.

Further information on NanoStabilizer®-LT is available here, and many additional Q&As have been addressed during this cannabis processing-related webcast.

Q2. How much NanoStabilizer®-LT should I use with my CBD isolate?

When making a highly translucent nanoemulsion, we recommend using 5 parts of NanoStabilizer®-LT to 1 part of your cannabis extract or isolate, by mass (5:1 ratio). A lower ratio may be used if translucency is less essential. The dependence of droplet size and translucency parameters on the NanoStabilizer®-LT:isolate ratio in a series of 20 mg/ml CBD isolate nanoemulsions is shown below:

|

Q3. We use your NanoStabilizer®-LT with BSP-1200 processor and are able to make very translucent CBD nanoemulsions. We have not, however, been able to make them tasteless - some bitterness always remains. Does it come from our CBD or NanoStabilizer®-LT? How can we reduce it?

NanoStabilizer®-LT itself is tasteless and is not where the bitterness comes from. To confirm this, you can make and taste a "blank" nanoemulsion with just NanoStabilizer®-LT and no CBD.

Cannabis extracts and isolates, on the other hand, are bitter, although they may not be perceived to be so when tasted directly because they do not dissolve in our saliva. Formulating these substances as nanoemulsions makes them water-compatible, and while doing so increases their bioavailability, it also allows our taste buds to perceive their bitterness.

Further information on this, along some strategies you can use to mitigate the issue, can be found here.

Q4. Will you provide the list of NanoStabilizer®-LT ingredients that I can use on my product label?

Yes. A Specifications Sheet with a list of ingredients and a Certificate of Analysis will be provided with purchase. NanoStabilizer®-LT comprises food-grade (GRAS) carrier oils, emulsifiers and preservatives, all tasteless and derived from natural sources.

Q5. What is the shelf life of NanoStabilizer®-LT and the resulting nanoemulsions?

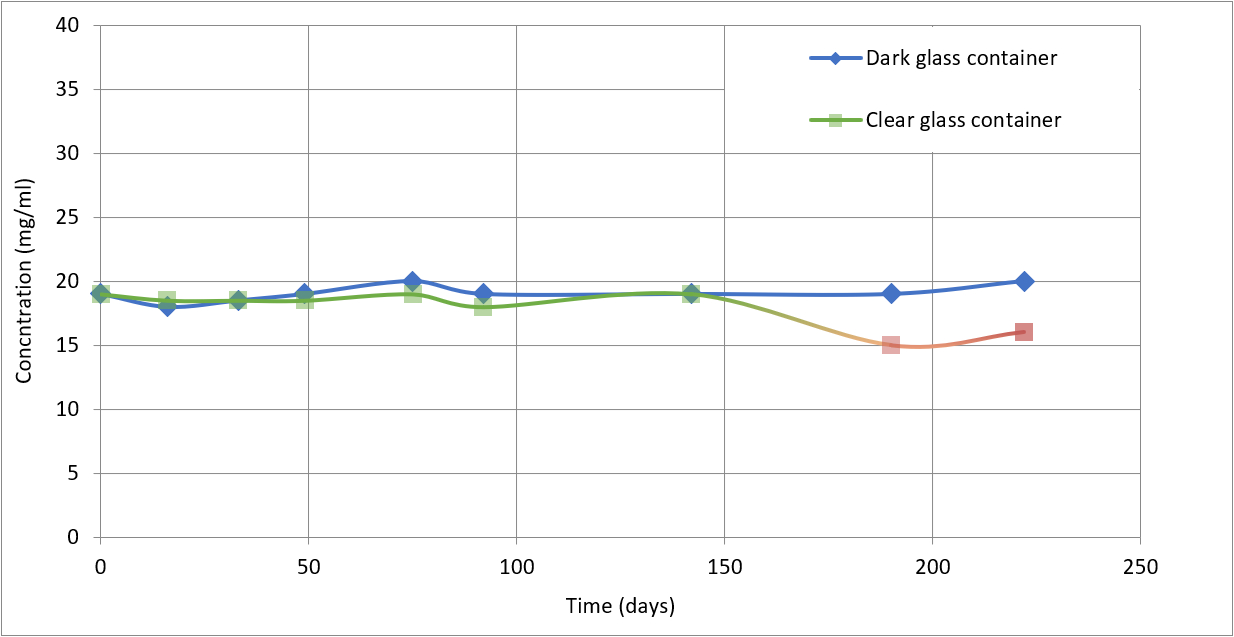

NanoStabilizer®-LT has the shelf life of 1 year and should be stored at 4 - 10 oC. A correctly prepared translucent nanoemulsion will exhibit permanent kinetic stability against oil-phase separation. Note that, as with any cannabis product, cannabinoid degradation may still occur due to exposure to light or microbial activity. The graph below shows typical stability data for a CBD-containing nanoemulsion based on the HPLC-monitored CBD concentration in the product:

The progressively pink portion of the graph (after about 150 days) corresponding to the sample stored in a clear glass container shows that oxidative CBD degradation is likely to eventually occur due to light exposure. In order to maximize its shelf life, we advise that you sterilize your finished nanoemulsion using a 220 nanometer-pore filter and store it in a dark-glass pre-sterilized (e.g., autoclaved) container at 4 - 10 oC.

Q6. Do I need to filter my NanoStabilizer®-LT-based nanoemulsion, and if so, what type of filter should I use?

Sterile-filtering your finished nanoemulsion is strongly recommended. It should be done immediately after the processing is completed by passing the nanoemulsion through a hydrophilic filter membrane with 220 nm pores. This post-processing step removes all particulate contamination, including microorganisms (sterilization), dust, titanium particles, leftover plant matter, etc. Filtration makes it unnecessary to manufacture nanoemulsions under aseptic conditions, which significantly reduces processing costs.

Since translucent nanoemulsions have much smaller droplet sizes (< 100 nm) than sterile-filter membrane pores (220 nm), they are able to flow though such filters without having any of the THC and/or CBD-containing oil droplets rejected by the membrane. The hydrophilic character of the filter membrane ensures that the hydrophobic oil droplets have low affinity for the membrane material and will not stick to it as long as they can fit through the pores and are carried by the liquid flow. You should, however, always make sure that your nanoemulsion is translucent before attempting to sterile filter it. Otherwise, some of the oil droplets may not fit through the pores and rapidly clog the filter. More information on this issue can be found here.

If you have any additional questions, please do not hesitate to contact us or leave a comment below.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)