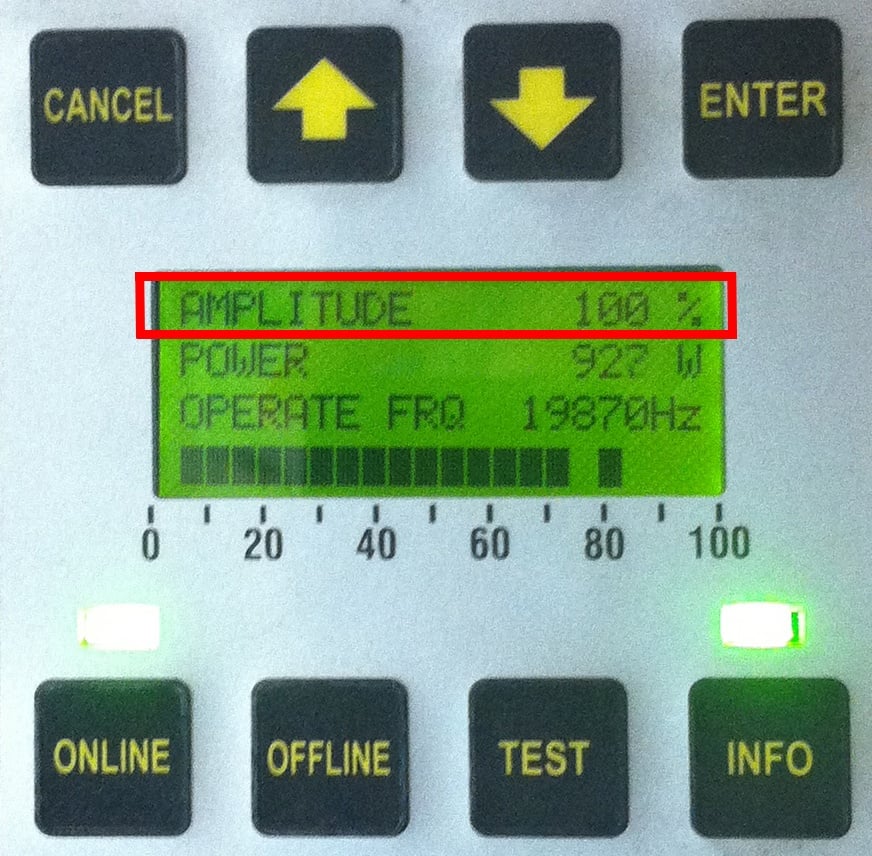

The ISP-3000 industrial-scale ultrasonic liquid processor is a Barbell Horn Ultrasonic Technology (BHUT)-based system designed for high-volume production. It can be implemented in two processing modes: flow-through and batch.

Although this ultrasonic processor is supplied mostly pre-assembled and ready-to-use, knowing how to put it together can be helpful. In this blog post we provide step-by-step assembly instructions for the ISP-3000 configured in the flow-through mode.

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)