One of the main challenges in the food & beverage industry is the inactivation of microorganisms (pasteurization). Thermal treatment of such products as milk and fruit-based beverages (generally, at over 70 °C) is currently the most commonly applied pasteurization method. Unfortunately, this approach causes significant deterioration of many of these products' attributes, such as flavor, color and nutritional quality. Alternative, non-thermal pasteurization methods that can not only ensure the microbial safety of the products, but also preserve their quality are, therefore, of great interest to this industry.

Alexey Peshkovsky, Ph.D.

Recent Posts

Ultrasonic Pasteurization of Milk and Water-Based Beverages

[fa icon="calendar'] Apr 16, 2016 5:29:03 PM / by Alexey Peshkovsky, Ph.D. posted in Food & Beverage

Acoustic Cavitation: Visual Examples of Chemical & Physical Processes

[fa icon="calendar'] Apr 10, 2016 12:45:02 PM / by Alexey Peshkovsky, Ph.D. posted in Theory of Ultrasonic Processing

In our previous blog post on ultrasonic cavitation in liquids, we described it as a cloud of low-pressure voids (a.k.a., vacuum bubbles or cavities) that grow, briefly oscillate and finally asymmetrically implode with great intensity. This effect causes extreme local temperatures and pressures, which can produce free radicals and give rise to many chemical (sonochemical) reactions. It also generates extremely powerful micro-jets and enormous shear forces, which promote a variety of physical (mechanical) processes. In some instances, these effects can be clearly seen as they occur. In this post, we provide such visual examples of chemical and mechanical processes.

Acoustic Cavitation: The Driving Force Behind Ultrasonic Processing

[fa icon="calendar'] Jan 2, 2016 5:01:34 PM / by Alexey Peshkovsky, Ph.D. posted in Ultrasonic Degassing, Theory of Ultrasonic Processing, Extraction, Food & Beverage, Wet Milling and Dispersing

Liquids exposed to high-intensity ultrasound can undergo acoustic cavitation. This phenomenon can typically be seen as a cloud of bubbles forming in the vicinity of the ultrasonic source (e.g., ultrasonic horn) and heard as an intense hissing noise. Cavitation is the formation of low-pressure voids (a.k.a., vacuum bubbles or cavities) in the liquid, which grow, briefly oscillate and then asymmetrically implode with great intensity.

6 Frequently Used Terms in Ultrasonic Processing of Liquids

[fa icon="calendar'] Dec 1, 2015 4:39:00 PM / by Alexey Peshkovsky, Ph.D. posted in Ultrasonic Processing Systems, Theory of Ultrasonic Processing, Extraction

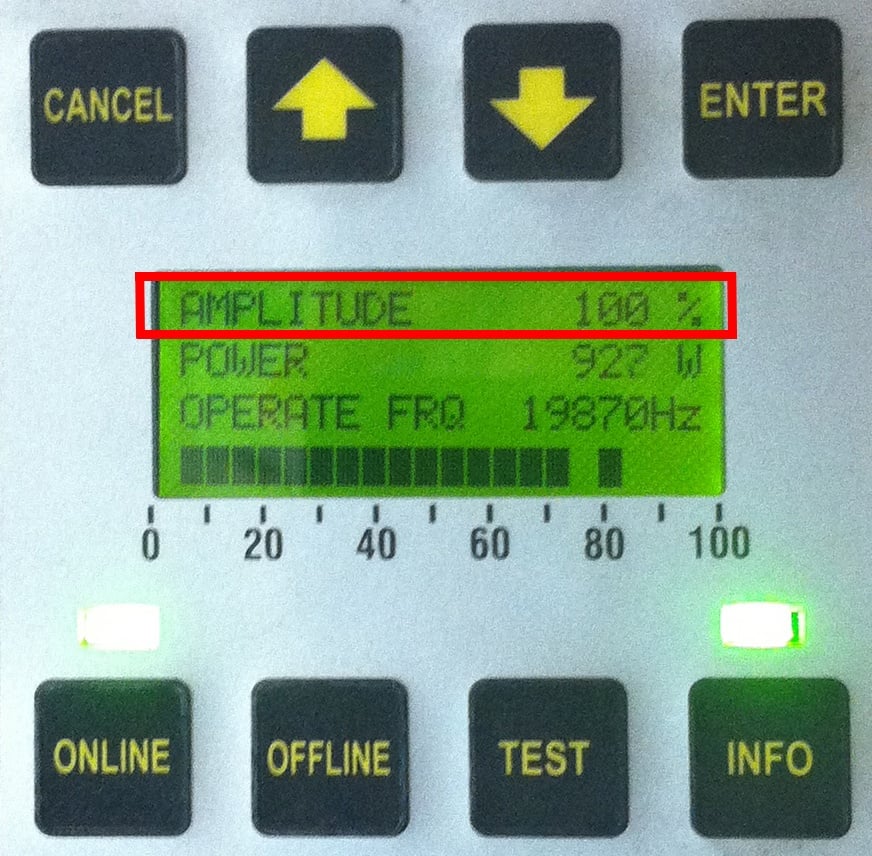

This blog post focuses on six common terms used in conjunction with ultrasonic processing: ultrasonic amplitude, power, frequency, power intensity, power density and processing rate.

Whether you use ultrasonic processing for making nanoemulsions, milling pharmaceutical crystals, degassing, extracting botanical oils, manufacturing bio-fuels, dispersing pigments, disrupting cells or enhancing a chemical process, there are several general terms you need to be familiar with. Knowing these terms and keeping track of the corresponding parameters will insure reproducibility of results and simplify process-related discussions with your peers.

Ultrasonic Production of Pharmaceutical Emulsions

[fa icon="calendar'] Aug 24, 2015 12:56:00 AM / by Alexey Peshkovsky, Ph.D. posted in Emulsion-based Products

Oil-in-water emulsions with nano-sized droplets (nanoemulsions) are widely used in the pharmaceutical industry, for example, as an intravenous source of fatty acids when oral nutrition is disadvantageous or as bioactive compound carriers (e.g. drugs, vaccines). Pharmaceutical nanoemulsions can be administered by almost all available routes including parenteral, ocular, nasal, oral, topical, and even aerosolization to the lungs. There are currently over a dozen commercially available drugs encapsulated into nanoemulsions. Small oil droplet sizes and the associated stability of these products are critically important.

Advantages of Ultrasound for Producing Emulsion Fuels

[fa icon="calendar'] Aug 1, 2015 8:38:00 AM / by Alexey Peshkovsky, Ph.D. posted in Emulsion-based Products

Combustion equipment (e.g., diesel engines, power boilers) emits significant amounts of hazardous gasses, such as Nitrous Oxides (NOx), hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2) as well as particulate matter (PM) and black smoke. Due to the widespread use of this equipment, the resulting damage to human health and the environment is tremendous. Adding 5 – 25% of water to the base fuel, such as diesel or kerosene, in the form of a very fine emulsion (nanoemulsion) significantly reduces these harmful emissions.

Scaling Up the Production of Stable Emulsion-Based Products

[fa icon="calendar'] May 28, 2015 2:04:00 PM / by Alexey Peshkovsky, Ph.D. posted in Emulsion-based Products, Process Scale-up

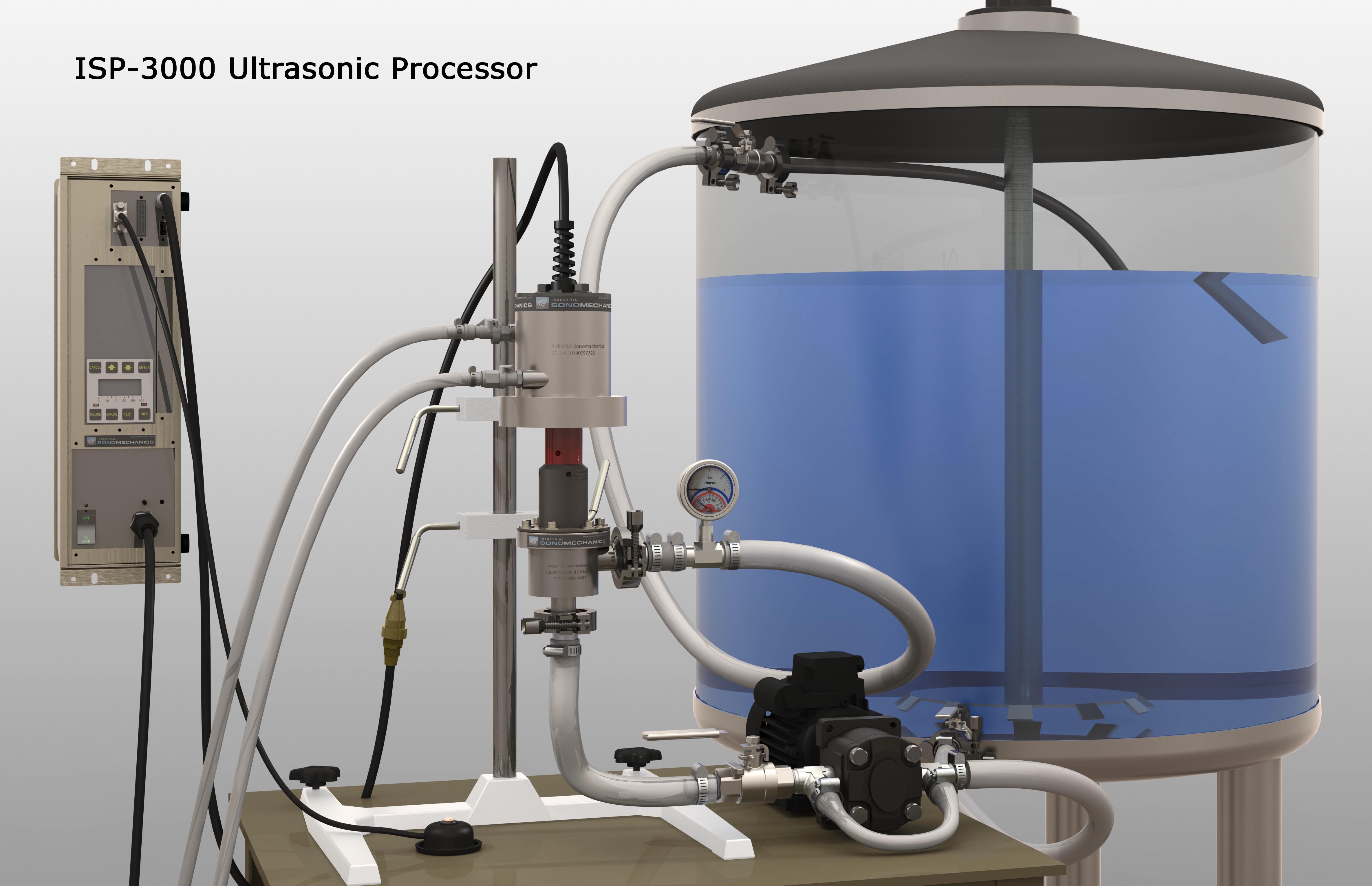

Are you able to make stable emulsions in the lab, but have trouble replicating the same result in the production environment? Scaling up an emulsification process is frequently even more challenging than succeeding at its lab optimization. In most cases, the post-scale-up loss of product stability is caused by the inability of industrial liquid processors to provide the same intensity of shear forces as was implemented during the research phase, which is why choosing the right production-scale equipment is fundamental.

Achieving Stability of Oil-in-Water and Water-in-Oil Emulsion Products

[fa icon="calendar'] May 9, 2015 4:38:00 PM / by Alexey Peshkovsky, Ph.D. posted in Emulsion-based Products

Do you need to make a product that comprises a homogeneous mixture of oil and water? Is stability of this product a major concern? If so, you are not alone. One of the biggest challenges faced by product developers and process engineers in a wide variety of industries is achieving long-term stability of products based on combinations of oil and water.

ISM's Ultrasonic Technology Development Achievements During 2014

[fa icon="calendar'] Feb 26, 2015 12:22:00 AM / by Alexey Peshkovsky, Ph.D. posted in General Announcements

.jpg?width=1994&height=332&name=Logo%20Sonomechanics%20White%20No%20Shadow%20R_Final%20(1).jpg)